11:00 am

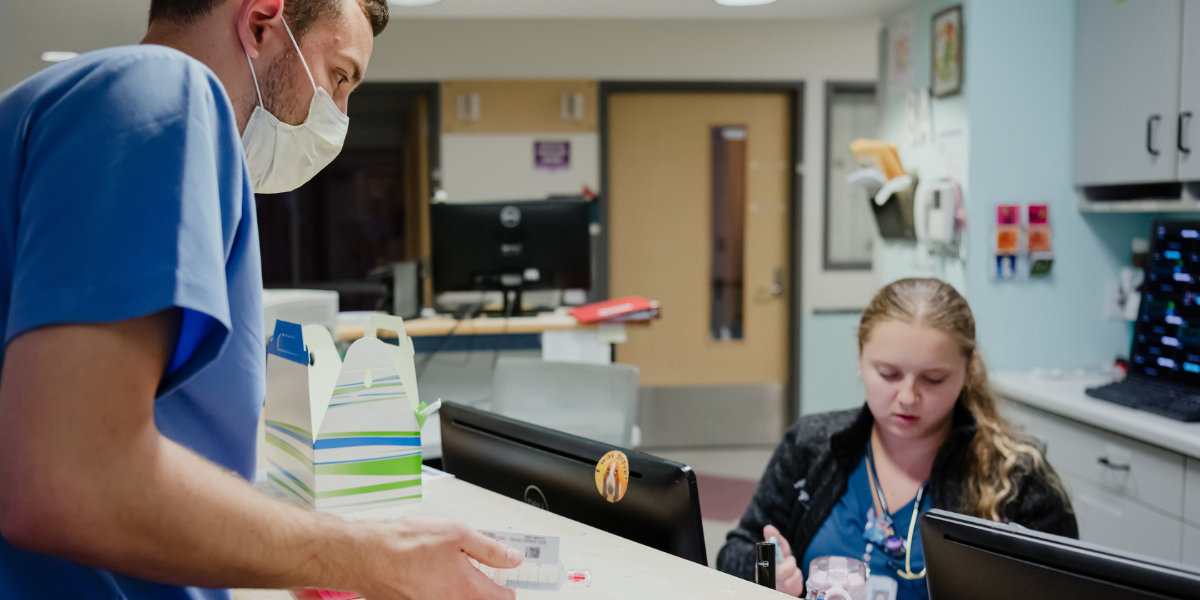

Twenty-four hours a day, Connecticut Children’s Central Pharmacy is a brightly-lit hive of activity. Today, pharmacy technician Gina Masselli prepares oral medication syringes. The Pharmacy prepares about 300 oral syringes per day. Gina pulls a medication label from the printer, locates the medication and logs into the EPIC system. She scans both the patient-specific barcode on the label and the medication’s barcode. After finding the correct oral syringe size, based on the volume of medication to be prepared, she draws up the correct dose into the syringe. She applies the patient label and checks to see if there should be additional labeling on the dose (such as “keep refrigerated”). She caps the syringe and puts it with the medication it was prepared from, indicating that it is ready for the pharmacist to conduct a final check.

Latest Articles

Connecticut Children’s and Xerox: Transforming Pediatric Healthcare with AI

HuskyTHON Students Dance Their Way Past $2 Million